Our product spectrum includes in total more than 10.000 vibrators and parts. Whether you require a pneumatic, hydraulic or electric vibrator - we supply the adequate and commercially proven drive.

Learn More...

Complete Vibration Solutions

NetterVibration is a leading supplier for vibration technology. Our strength is in our ground breaking technology and the application knowledge of our employees based on more than six decades of experience.

Learn More...

Learn About Us

If you are looking for a tailor-made solution for your problem, we have the right answer - whether you want to convey, sieve, dose, compact or solve an unusual application with vibration technology.

Learn More...

Preventing Clogging On Hoppers

Do you need solution proposals that are precisely tailored to your requirements? Please fill out the questionnaire suitable for your application and our application engineers will be happy to assist you.

Learn More...

Technical Questionnaires

Do you need assistance? We will be on hand for help and advice. Outline your request; we will find a solution together.

Learn More...

Talk With Our Engineers

We will gladly take on your wishes: together with you we will develop solutions for your application. Our experienced specialists know your line of work and the necessary “tricks”.

Learn More...

We Can Make It!

NetterVibration - In the service of vibration technology since 1953

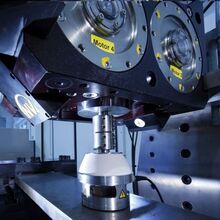

Intelligent vibration technology from NetterVibration

NetterVibration holds – thanks to its wide experience – a leading position in the field of vibration technology and stands, since 1953, for “Serving industry with vibration”.

Productive and intelligent solutions, technical expertise and “Made in Germany” quality form the basis of success. Vibrators from NetterVibration are applied in numerous industrial sectors as in, for example, chemical, food, construction or mechanical engineering ones. Complete vibration facilities such as vibration tables and dosing and conveyor troughs are part of our range of services.

NetterVibration offers efficient and reliable solutions in vibration technology. These include conveying, separating, dosing, releasing, compacting, sorting and sieving of bulk materials such as powders, pellets or granulate materials.

Moreover, with vibrators from NetterVibration hoppers, pipes can be emptied and walls cleaned, as well as product jams loosened. Proven solutions for concrete compaction for the construction industry are available.

NetterVibration develops customized vibration solutions for all specific applications in close collaboration with its customers. This often results in unique products such as the extremely low-built drive unit LineDrive for conveyor or dosing channels, or roller vibrators for extremely high temperatures (500 °C). Experienced sales representatives and application engineers gladly advise you on-site.

![vibration technology for dosing in the production process [Translate to English:] Dosierung](/fileadmin/_processed_/b/c/csm_dosing_2a4c9d42c7.jpg)