Notre gamme de produits englobe au total plus de 10 000 vibrateurs et pièces. Que vous ayez besoin d’un vibrateur pneumatique, hydraulique ou électrique – nous vous fournirons un entraînement qui convient et qui a fait ses preuves.

En savoir plus...

Solutions complètes de vibration

NetterVibration est un acteur majeur des technologies de vibration. Notre force réside dans notre technologie de pointe et le savoir de nos collaborateurs en matière d’applications sur la base de plus de 60 années d’expérience.

En savoir plus...

En savoir plus sur nous

Vous êtes à la recherche d’une solution sur mesure pour votre production? Nous avons la réponse qu’il vous faut – qu’il s’agisse de convoyer, de doser, de compacter ou que vous souhaitiez une application exceptionnelle de vibration.

En savoir plus...

Prévenir le colmatage des trémies

Vous avez besoin de propositions de solutions précisément adaptées à vos besoins ? Veuillez remplir le questionnaire adapté à votre demande et nos ingénieurs d'application seront heureux de vous assister.

En savoir plus...

Questionnaires techniques

Vous avez besoin d’aide? Nous nous ferons un plaisir de vous faire bénéficier de nos conseils et de notre assistance. Expliquez-nous quel est votre problème, nous trouverons ensemble une solution.

En savoir plus...

Contactez nos ingénieurs

Nous répondons à vos attentes: en coopération avec vous, nous mettrons au point des solutions pour votre application. Nos spécialistes connaissent votre branche et les « astuces » nécessaires.

En savoir plus...

Solutions sur mesure

NetterVibration - Au service de la technologie depuis 1953

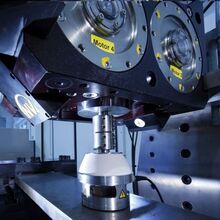

Technologie vibratoire intelligente de NetterVibration

NetterVibration s’appuie sur près de 70 ans de « vibration au service de la technique » et détient, grâce à cette vaste expérience, un leadership international dans le domaine des technologies de vibration. Des solutions productives et intelligentes, un savoir-faire technique et la qualité « Made in Germany » sont les clés de notre succès. Les vibrateurs de NetterVibration sont utilisés dans de nombreux domaines industriels tels que les industries chimique, alimentaire et du bâtiment ou les constructions mécaniques. Des installations de vibration complètes, telles que des tables vibrantes et des goulottes de dosage et de convoyage, font également partie de la gamme de prestations.

NetterVibration offre des solutions efficaces et fiables. En font partie le convoyage, la séparation, le dosage, le desserrage, le compactage, le tri et le tamisage de matières en vrac telles que des poudres, des pellets ou des granulats.

Par ailleurs, les vibrateurs de NetterVibration permettent de vider des réservoirs et des canalisations, de décolmater des parois et d’éliminer les blocages de produits. Le bâtiment bénéficie de solutions éprouvées centrées sur le compactage du béton.

En étroite coopération avec ses clients, NetterVibration met au point des solutions sur mesure destinées à toutes les applications spécifiques. Il en résulte fréquemment des produits uniques en leur genre, par exemple l’unité d’entraînement LineDrive, d’une hauteur extrêmement faible, destinée aux goulottes de convoyage ou de dosage, ou les vibrateurs à rouleaux pour températures extrêmement élevées (500°C). Les collaborateurs expérimentés de notre force de vente et nos techniciens en applications se feront un plaisir de vous conseiller sur votre site.

Quelle est la bonne solution pour vous?

Besoin d'aide? Contactez-nous pour une assistance : +33 973037778

![[Translate to French:] Dosierung](/fileadmin/_processed_/b/c/csm_dosing_2a4c9d42c7.jpg)