Food Industry

Efficient Dosing and Screening of Fruit Granules with Precise Vibratory Conveyor System

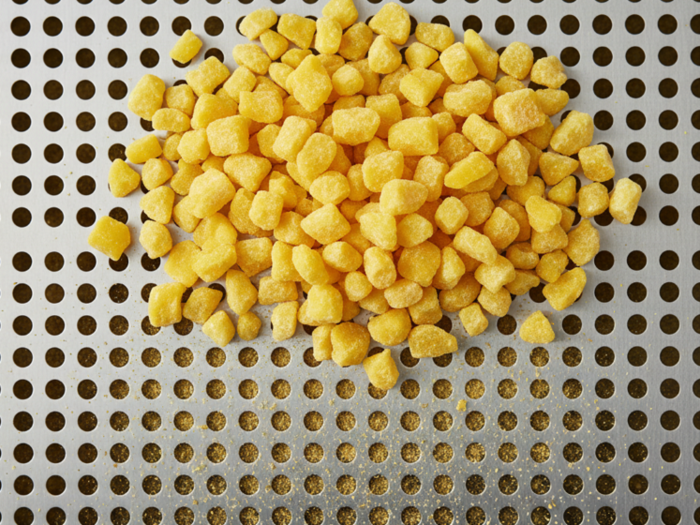

In food processing, precise dosing, uniform product quality, and high throughput are essential. A manufacturer needed a solution to accurately dose small fruit pieces while ensuring they did not fall below a defined minimum size. The previous method was inaccurate, slow, and did not allow uniform distribution. Strict hygiene standards also had to be met.

- Screening by minimum size for consistent quality

- Fast dosing for continuous production

- High hygiene standards in food processing

Our solution

The customer implemented a PowerPack conveyor system with NTS pneumatic piston vibrator. The target feed of 5.6 kg in 4.25 seconds is reliably achieved. The vibration technology enables rapid and precise separation and dosing of fruit granules. The stainless-steel construction meets the highest hygiene standards and is easy to clean.

Our advantages

- Precise separation and consistent dosing quality

- High process speed: 5.6 kg in 4.25 seconds

- Compliance with strict hygiene standards

- On-site support and advice from trained field engineers