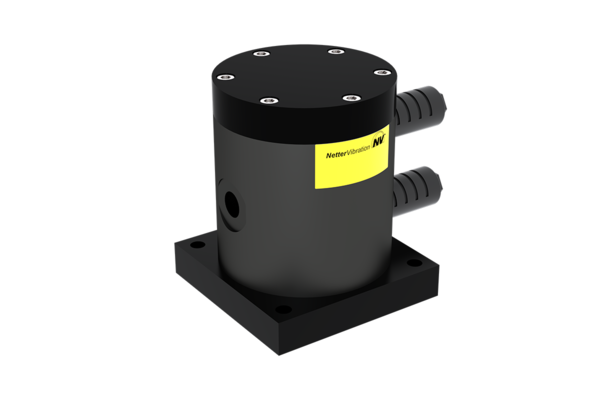

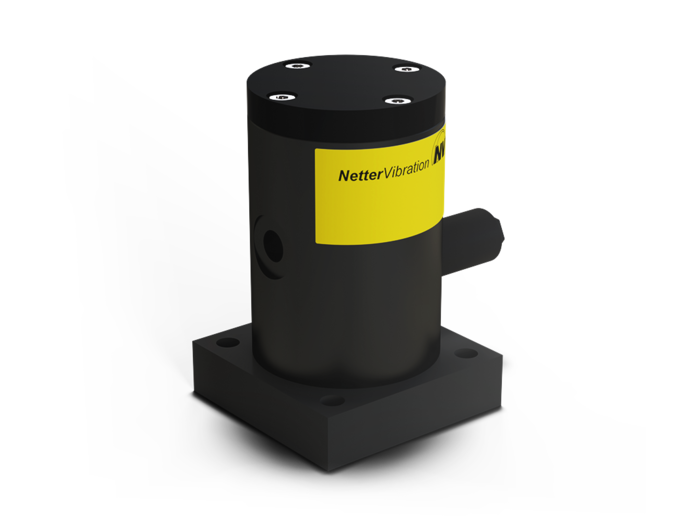

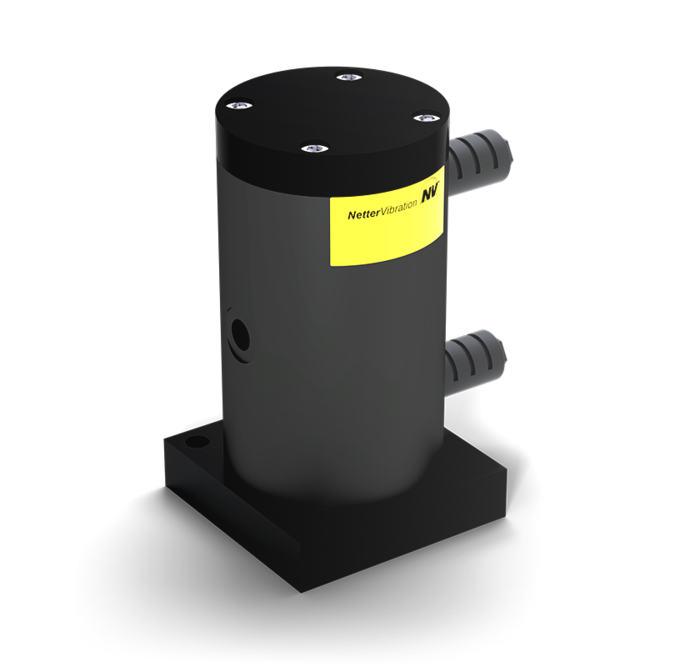

Series NTS Pneumatic Piston Vibrator

The all-rounder – precise, robust, versatile

Areas of application

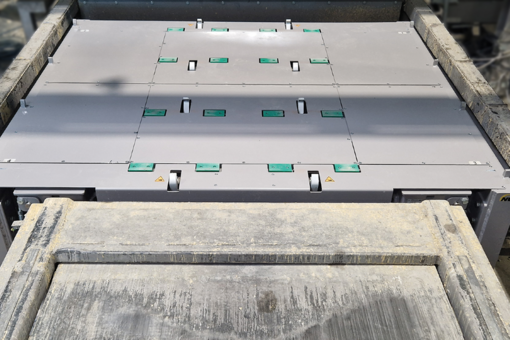

- Conveying, compacting and loosening bulk materials

- Bunker discharge and material extraction assistance

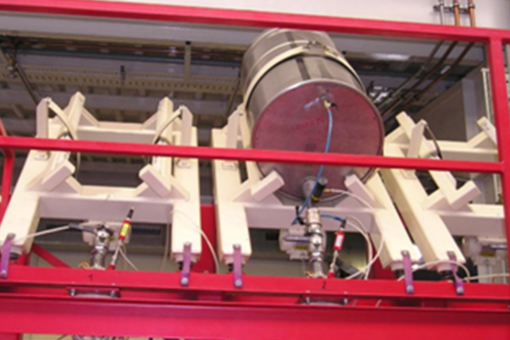

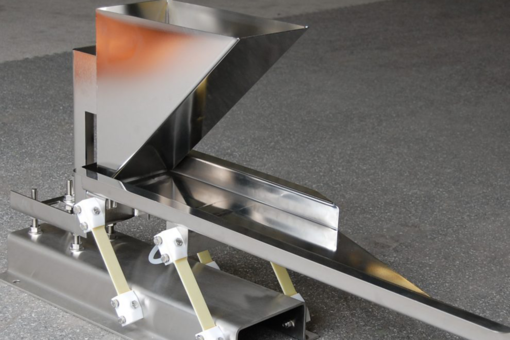

- Drive unit for conveying and discharge troughs in combination with PowerPack / DosyPack

- Optimisation of material flow across a wide range of industries

- Synchronous operation of multiple vibrators for complex applications

Highlights

- Linear vibration behaviour for effective and precise conveying

- Sinusoidal vibration for uniform material movement

- Infinitely adjustable frequency with separately adjustable amplitude

- Start and stop in any mounting position without delay

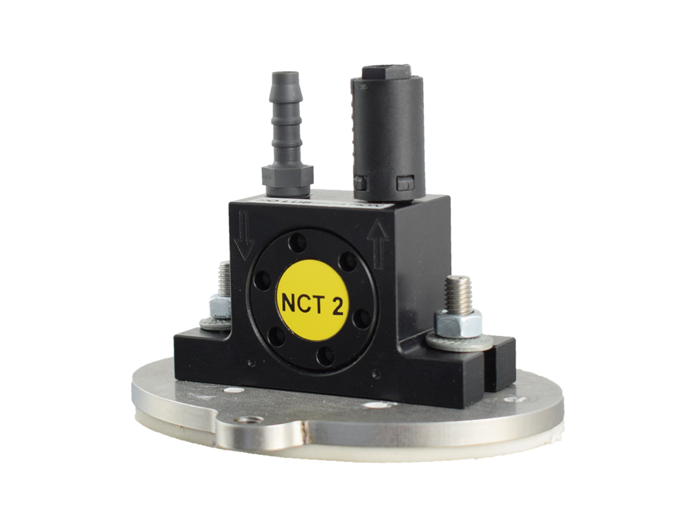

- Versions for oil-free operation (L), ATEX-compliant designs (E) and stainless steel housings (S) available

Datasheet & more

Go to downloadsDescription

Thanks to their linear vibration behaviour, NTS series pneumatic piston vibrators are particularly suitable for conveying, compacting and loosening bulk materials. They are frequently used for bunker discharge and as drive units for conveying and discharge troughs.

The vibration (sinusoidal oscillation) is generated by a freely oscillating, self-controlled piston. This vibration supports and optimises material flow in numerous industrial applications. NTS piston vibrators start and stop without delay in any mounting position.

A special feature of the NTS vibrators is the ability to synchronise multiple units. The frequency is infinitely adjustable via the operating pressure, while the vibration amplitude can be set using an optional throttle.

For optimal selection of the appropriate variant, we recommend individual consultation.

Our technical consultants will be pleased to assist you in selecting and positioning your vibrator or impactor.

Please contact us here.