Chemical & Pharmaceutical Industry

Removing Viscous Liquids from Drums: How Vibration Technology Speeds Up Discharge and Minimises Residual Volumes

A chemical company was experiencing difficulties when emptying a highly viscous liquid from drums. The small discharge opening combined with the high viscosity significantly slowed down the process.

- High time consumption and inefficient processes

- Material losses due to residual volumes remaining in the drum

- Increased cleaning effort

Our solution

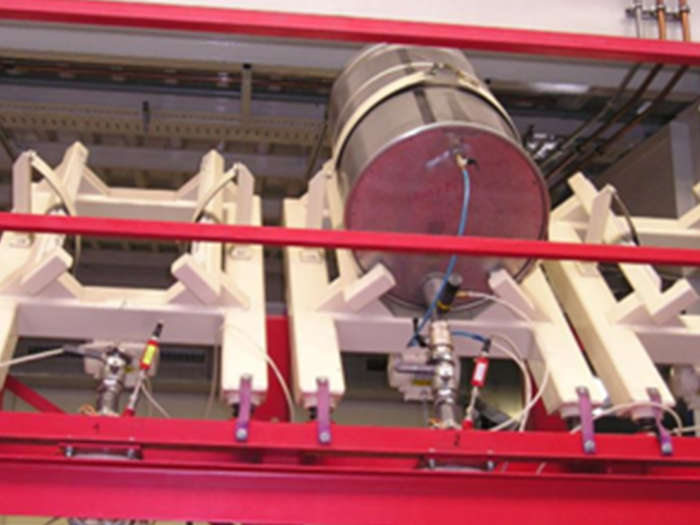

NetterVibration used the pneumatic piston vibrator NTS, mounted directly on the drum or the discharge station. The linear vibrations mobilise the liquid towards the outlet, accelerating the discharge process.

The uniform movement of the drum contents significantly reduces emptying time, while the vibration also loosens stubborn residues, allowing the drum to be emptied almost completely.

Our advantages

- Significantly reduced emptying times

- Minimised residual volumes

- Reduced cleaning effort

- Easy integration into existing systems