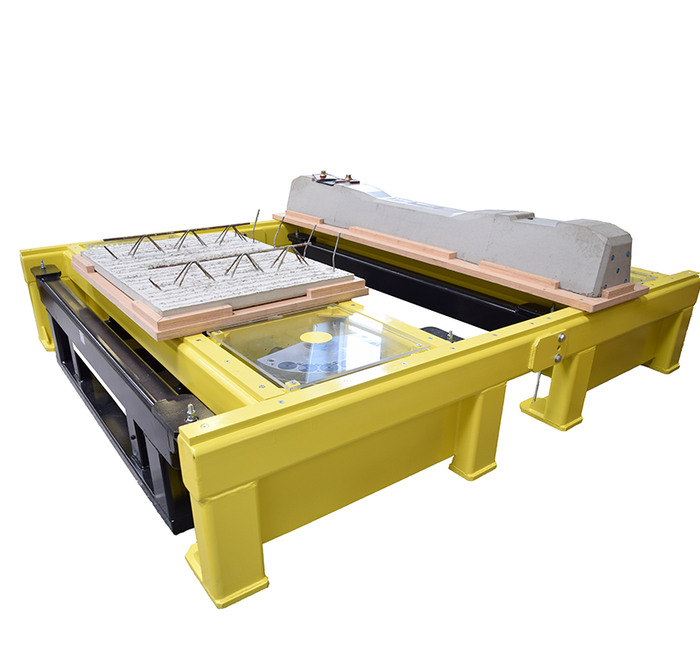

Series GyroShake Concrete Shaking Station

The Quiet Concrete Shaking Station – Low Noise, High Performance

Apllications

- Compaction of precast concrete elements such as floor slabs, double-wall panels, garage floors, or railway sleepers

- Production of exposed concrete with an almost pore-free surface

- Integration into pallet circulation systems for automated concrete processing

- Mixing or homogenizing difficult-to-blend emulsions or materials (e.g., for specialized mixes)

- Testing and simulation of dynamic loads or vibration resistance (e.g., test applications, material testing)

Highlights

- Low-noise operation – continuous sound level below 70 dB(A), even under heavy concrete loads

- High compaction performance and pore-free concrete – optimal air bubble displacement and uniform concrete distribution for dense, high-quality components

- Wide amplitude and high load capacity – suitable for heavy concrete or large molds

- Flexible motion control – longitudinal and transverse directions, with optional circular movement

- Customizable – designed to customer specifications and can be integrated into existing systems

Datasheet & more

Go to downloadsDescription

The GyroShake series of shaking stations from NetterVibration is a specialized solution for efficient, low-noise, and high-quality concrete compaction – ideal for precast concrete plants and serial production. The system combines powerful vibration drives with a patented suspension that supports a freely oscillating frame. This ensures a precisely controlled, loss-free frame movement and uniform energy transfer to the concrete form.

During operation, the electronic control allows frequency and amplitude of the vibrations to be flexibly and process-optimally adjusted. Movements can be performed longitudinally, transversely, or in combination, including circular motion – depending on the desired compaction pattern and type of concrete.

Thanks to the large unbalance motors and robust construction, even heavy concrete loads or large molds can be compacted safely and efficiently, without overloading the surrounding environment – the noise level remains below 70 dB(A), making it suitable for noise-sensitive production environments.

The station is manufactured to customer specifications and can be easily integrated into existing precast and pallet circulation systems. For production facilities regularly producing concrete elements, GyroShake offers a consistent, reliable, and cost-effective solution.

For the ideal configuration and optimal application, we recommend individual consultation – please use the contact options provided on this page.