Realistic Vehicle Simulation – Testing Engine Vibrations with NetterVibration’s PowerCube

In automotive research, precise simulation of vehicle movements is crucial to test the performance and durability of components. Especially in the development of movable suspensions, realistic vibrations in all spatial axes must be replicated to compare theoretical calculations with practical results. Tests must be axis-specific, variable, and repeatable to analyse stresses and material behaviour under real conditions.

- Previous systems did not allow isolated vibration in individual axes

- Limited test quality increased the risk of incorrect calculations

- Limited adjustment of frequencies and amplitudes restricted test variety

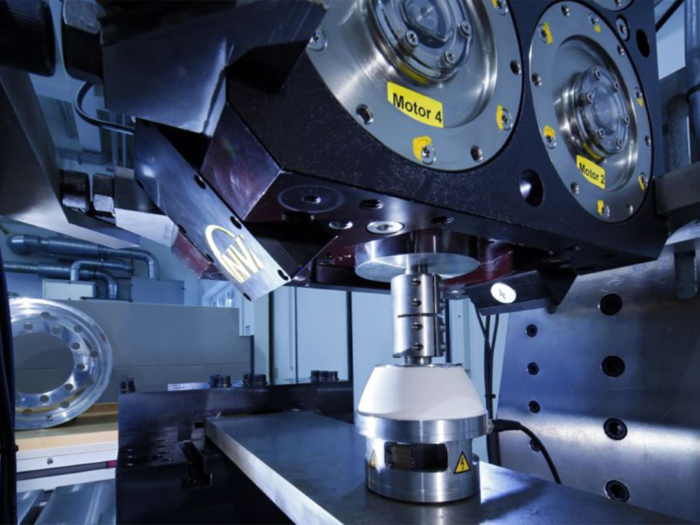

The research institute employed NetterVibration’s multi-axis vibration system PowerCube (VectorDrive) to realistically simulate engine movements. The system delivers forces up to 20 kN and frequencies up to 200 Hz for maximum testing flexibility. Adjustable amplitudes allow simulation of a wide range of real driving conditions.

- Realistic test conditions for accurate comparative data

- Precise stress analysis along single or multiple axes

- Flexibility through adjustable amplitudes and axes

- Efficient validation of component performance and durability