Series VectorDrive Multiple-Shaft Vibration Systems

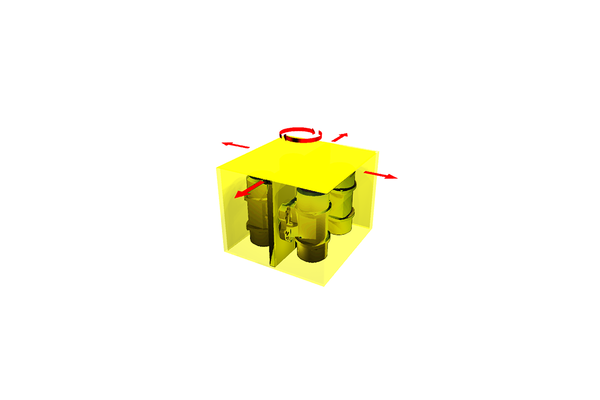

The Powercube - resonance-free, flexible, future-ready

Areas of Application

- Compaction and loosening of bulk materials with variable direction of action

- Mixing and distribution of materials in industrial processes

- Testing applications, e.g. test rigs, material testing, quality control

- Simulation of dynamic loads on components

- Applications with changing or special requirements regarding vibration direction, frequency or amplitude

Highlights

- Resonance-free start and stop – no transition through harmful resonance ranges

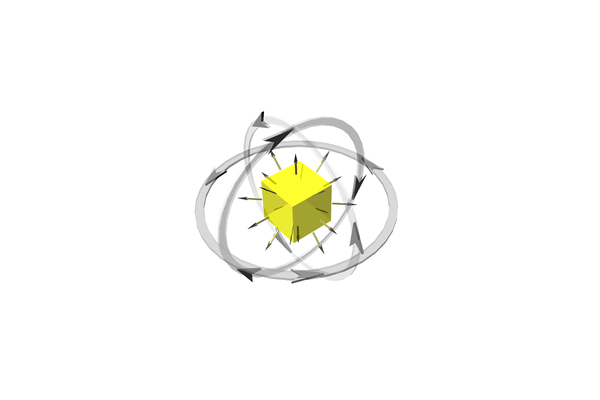

- 100% controlled vibration in any direction – generation of circular and linear motion

- Continuous amplitude and frequency control during operation

- Constant acceleration even with varying loads

Datasheet & more

Go to downloadsDescription

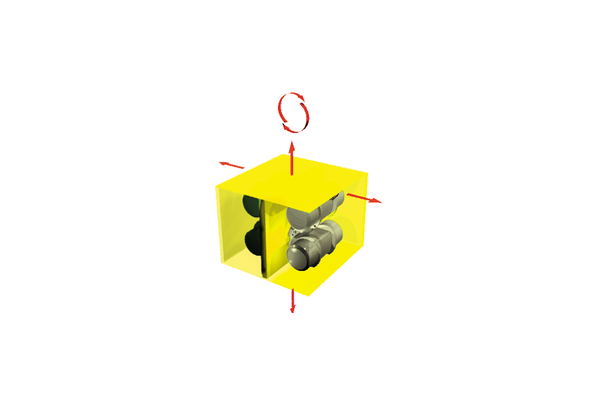

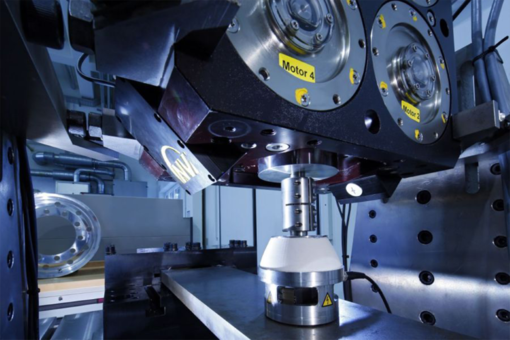

The VectorDrive multi-shaft vibration system from NetterVibration is an innovative solution for industrial applications requiring highly flexible, precise and adaptable vibration. The system consists of a central control unit and multiple vibrators (at least four) operating in combination. This configuration allows independent adjustment of direction vector, frequency and amplitude, even during ongoing operation.

Thanks to intelligent control, VectorDrive enables resonance-free start-up and shutdown. Harmful resonance phases during run-up or run-down are avoided – a decisive advantage for sensitive materials and precision applications.

Example: Bulk material is optimally compacted by external vibrators at 3,000 rpm. When passing through speeds between 1,700 rpm and 1,300 rpm, unwanted loosening may occur. Ideally, vibration should be switched on and off directly at nominal speed. VectorDrive control enables exactly this “on/off” effect: within fractions of a second, the unbalances are positioned relative to each other to generate the desired centrifugal force and direction of action.

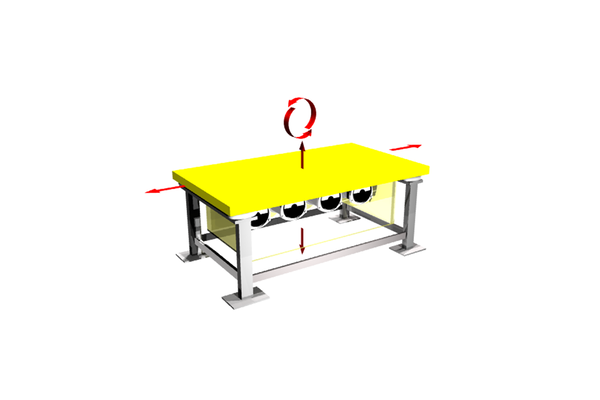

Depending on the arrangement of the vibrators – for example horizontally or vertically beneath a vibrating plate or table – the system generates either circular or linear vibrations. The resulting force direction can be precisely aligned, offering maximum flexibility for mixing, compacting, screening or testing processes.

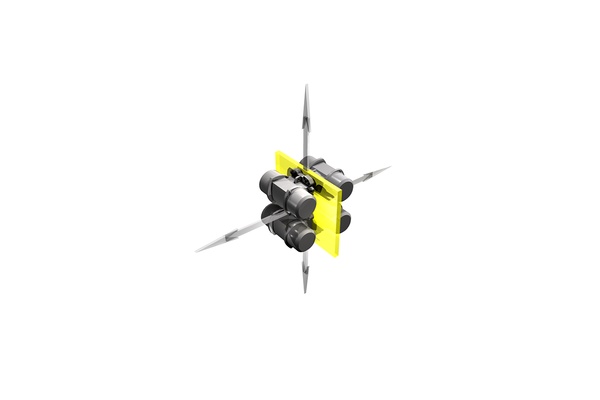

A preferred mounting and reorientation concept is the so-called PowerCube – a modular vibrator cube that can be easily mounted, removed or rotated to change vibration direction (vertical / horizontal) or positioning.

VectorDrive is the ideal solution when conventional vibrators with fixed motion directions reach their limits – for example in complex material handling, mixing processes, dynamic test rigs or applications with changing requirements. With VectorDrive, processes become more efficient, precise and reproducible.

For individual adaptation and optimal system configuration, we recommend personal consultation – please use the contact options on this page.