Series NEG Electric External Vibrator (Three-Phase AC)

The three-phase unbalance motor – powerful, robust and maintenance-free

Areas of application

- Versatile use for conveying, discharging, compacting, emptying, screening and more

- Drive unit for conveying troughs, vibrating tables and screening machines

- Elimination of material blockages and adhesions in silos, hoppers and containers

- Concrete compaction, e.g. on formwork in precast plants or tunnel construction

Highlights

- Robust mechanical design with generously sized rolling bearings for high operational reliability and long service life

- Flexible three-phase operation (230/400 V at 50 Hz, 60 Hz and additional voltages available) with various pole numbers

- Smooth housing surface and stainless steel unbalance covers for corrosion resistance and easy cleaning

- ATEX versions available for use in potentially explosive atmospheres

Datasheet & more

Go to downloadsDescription

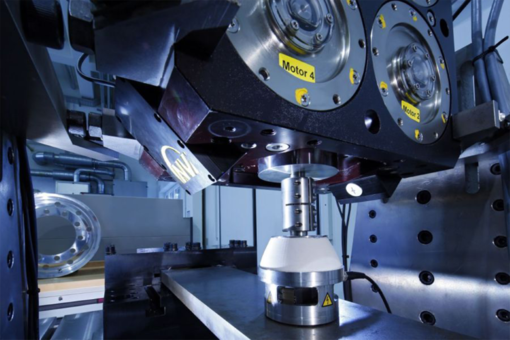

The NEG series three-phase electric external vibrators provide a proven and robust solution for industrial applications where conveying, screening or discharge systems must be vibrated reliably—both under standard conditions and in harsh operating environments (protection class IP66-7 or IP65 depending on the housing, insulation class F).

The drive is provided by a three-phase asynchronous motor operating at 230/400 V (50 Hz). Depending on the pole number and mains frequency, operating speeds range from 750 to 3,000 rpm (approximately 20 % higher at 60 Hz). Adjustable unbalance weights on both shaft ends generate circular vibration, which is transmitted evenly and reliably to the connected structure. All units are suitable for operation with frequency inverters, and the terminal box is integrated into the housing.

The mechanically robust design with generously dimensioned rolling bearings ensures high operational safety and long service intervals—even during continuous operation or in demanding production environments. Stainless steel unbalance covers and the smooth housing surface further simplify cleaning and maintenance, making the NEG series particularly suitable for applications with increased hygiene or corrosion-resistance requirements. The NES series offers corresponding versions with a fully stainless steel exterior.

Thanks to its flexibility, the NEG series is suitable for a wide range of industrial processes—from conveying and discharging bulk materials to screening applications and concrete compaction.

For optimal selection of the appropriate variant, we recommend individual consultation.

Our technical consultants will be pleased to assist you with the selection and positioning of your vibrator or impactor.

Please contact us here.