Construction Materials Industry

Automated Concrete Compaction for Precast Elements: Pneumatic Vibrators Ensure Maximum Strength and Density

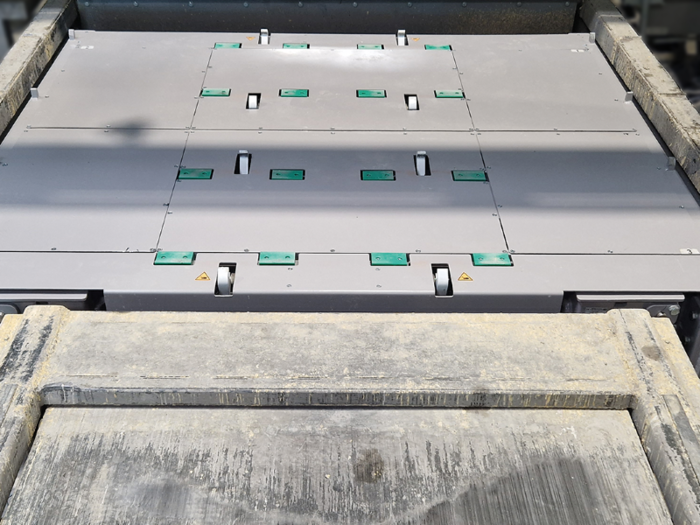

For the automated production of precast concrete elements, freshly poured concrete had to be reliably compacted immediately after filling the moulds. The objective was consistent, reproducible component quality combined with high throughput. The customer required a robust solution that could be seamlessly integrated into a continuous circulation system.

- Insufficient compaction leads to air inclusions and reduced strength

- Inhomogeneous density impairs water tightness and durability of precast elements, resulting in scrap

- Slow or non-automated compaction processes reduce efficiency in circulation production

Our solution

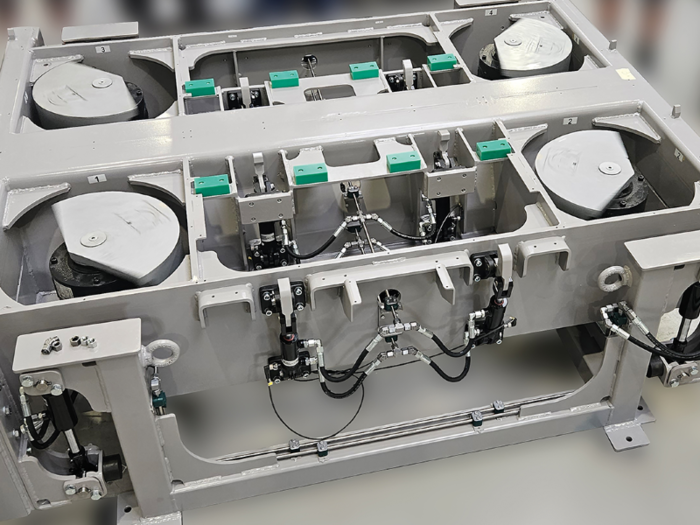

The customer uses multiple NTS pneumatic piston vibrators mounted beneath an existing vibrating table. Professional installation and precise adjustment by NetterVibration specialists ensured the optimal vibration frequency for fresh concrete. Custom-designed mounting brackets provide secure, vibration-optimised integration into the existing system.

Our advantages

- Significantly improved component density for high strength and load-bearing capacity

- Reproducible quality within an automated production process

- Reduced scrap rates and stable production workflows

Linear Vibrators

Series NTS

Pneumatic Piston Vibrator

Cleaning

Dosing

Emptying

Feeding

Loosening

Sieving

Sorting

Testing and Simulation

Compacting

Show productseries

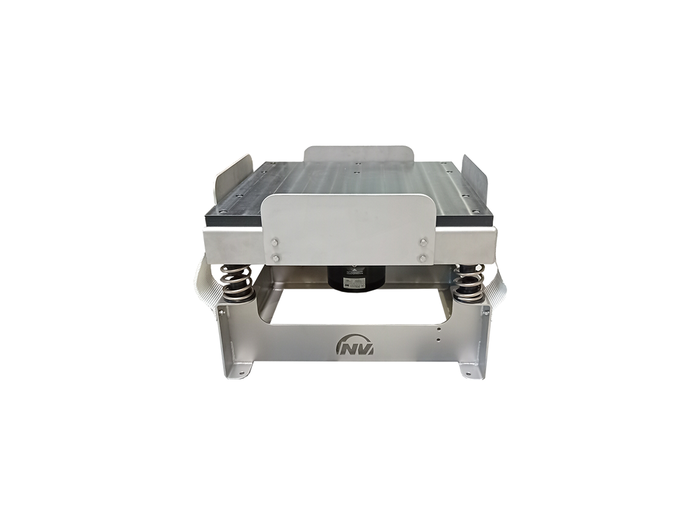

Vibrating Tables

Series VT

Standard Vibrating Tables

Loosening

Sorting

Testing and Simulation

Compacting

Packaging

Concrete compaction

Show productseries