Consumer Goods Industry

Efficient Filling of Octabins with Plastic Closures Using Horizontal Vibration for Maximum Space Utilisation

The packaging industry – particularly in the food & beverage, automotive, and pharmaceutical sectors – places high demands on the efficiency and precision of filling packaging units. Plastic closures must be packed compactly, safely, and without damage to minimise transport costs and optimise logistics processes.

- Uneven distribution of closures inside the carton

- Insufficient space utilisation leading to higher transport costs

- Time-consuming manual readjustment

- Risk of damage due to improper filling

Our solution

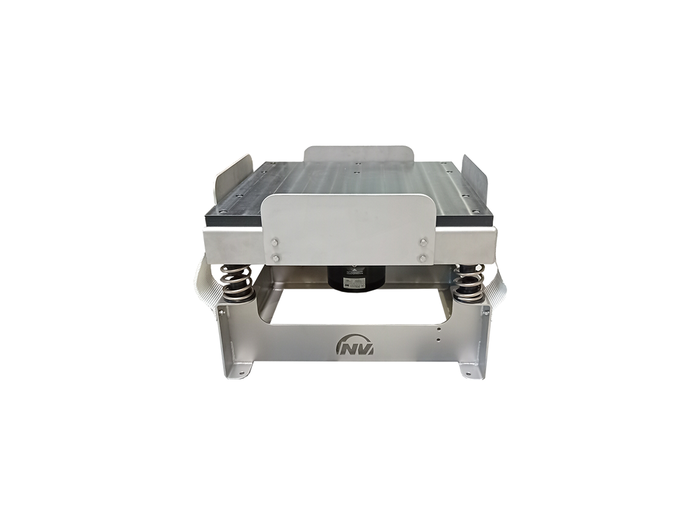

Using a vibrating table equipped with the pneumatic linear vibration system NTK and a FlexiLink coupling, the filling process was automated and optimised.

- Horizontally operating vibrating table with lateral leaf springs and large vibration amplitude

- Resonance-optimised operation with low compressed air consumption

- Integration into the customer’s digital control system for flexible adjustment of duration and intervals

- The subsequent purchase of ten vibrating tables confirms the high process reliability

Our advantages

- Maximum space utilisation: no voids in cartons – up to 100% fill rate even in challenging areas

- Time savings through automated filling

- Reduced material usage through optimal carton utilisation and lower transport costs

- High process reliability: stable pallets and minimised risk of transport damage

Vibrating Feeders, Dosing and Screening Systems

Customised Conveyors and Dosing Systems

Dosing

Feeding

Sieving

Sorting

Show productseries

Linear Vibrators

Series NTK

Pneumatic Piston Vibrator

Cleaning

Dosing

Emptying

Feeding

Loosening

Sieving

Sorting

Testing and Simulation

Compacting

Packaging

Show productseries

Vibrating Tables

Series VT

Standard Vibrating Tables

Loosening

Sorting

Testing and Simulation

Compacting

Packaging

Concrete compaction

Show productseries