Customised Conveyors and Dosing Systems

Customised Feeding and Dosing Systems – Compact, Robust, Efficient, Durable

Areas of Appliation

- Feeding and dosing bulk materials in the food industry

- Separating and sieving powders and granules in chemical and pharmaceutical industries

- Material preparation in construction and ceramics

- Filling and packaging processes in plastics and metal industries

- Applications with high hygiene standards or ATEX requirements

Highlights

- Custom design to meet individual operational requirements

- ATEX and stainless steel options for diverse applications

- Driven by pneumatic or electric vibrators

- High precision in feeding and dosing processes

- Quick start and stop, easy to clean

- Easily adjustable for variable production requirements

Datasheet & more

Go to downloadsDescription

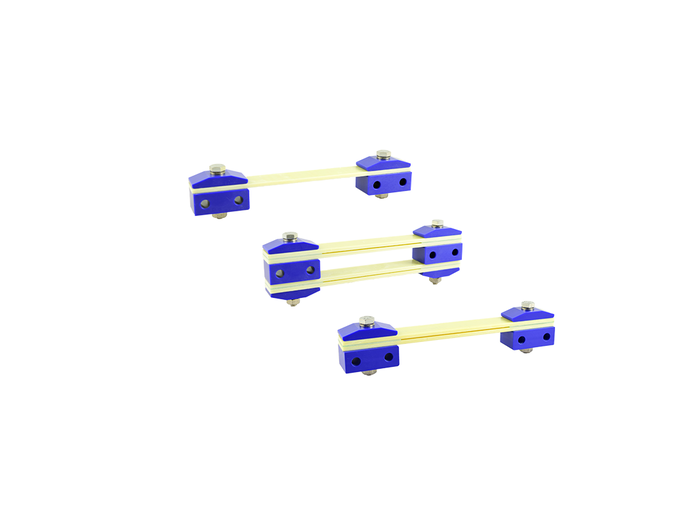

NetterVibration’s custom feeding and dosing systems are designed for precise, efficient, and flexible material handling. They are suitable for feeding, dosing, separating, and sieving bulk materials across multiple industries, including food, chemical, pharmaceutical, construction, ceramics, and plastics processing.

Systems can be tailor-made with ATEX or stainless steel designs for hygienic or explosion-protected environments. Powered by pneumatic or electric vibrators, they provide high accuracy and rapid response for starts and stops.

With easy cleaning, adjustable settings, and robust construction, these systems are flexible and optimised for continuous production. For the best selection of the suitable variant, we recommend individual consultation via the contact options provided.

Our specialists will gladly assist you in choosing your customised feeding and dosing system. Contact us here.