Series NTK Pneumatic Piston Vibrator

Tailored vibration power – robust, flexible, high-performance

Areas of application

- Conveying, compacting and loosening bulk materials

- Mechanical stimulation and influence of processes

- Use across a wide range of industries

- Applications requiring high amplitudes and variable stroke

- Drive for FlexiLink, NDL 25, troughs, vibrating tables and screens

Highlights

- Directional linear vibration for effective material movement

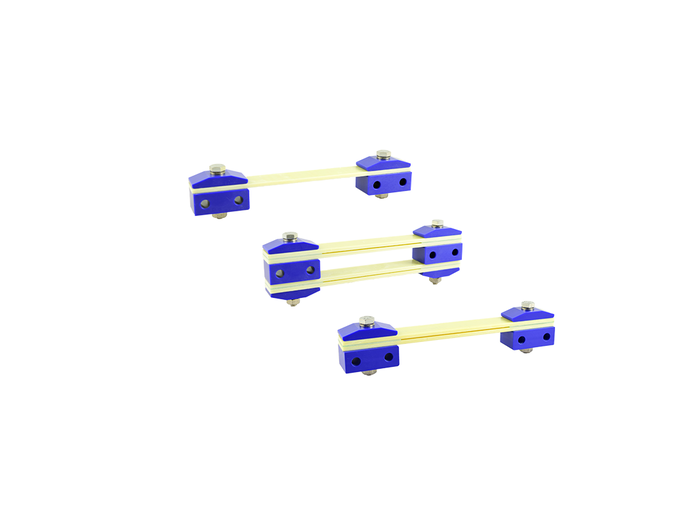

- Additional vibration masses for individual amplitude adjustment

- Frequency and stroke independently adjustable

- Start and stop in any mounting position without delay

- Versions for ATEX (E), stainless steel (S), oil-free operation (L), high temperature (HT) and low temperature (NT) available

- Optional dust protection for sensitive bulk materials

- Mounting possible on housing or piston

Datasheet & more

Go to downloadsDescription

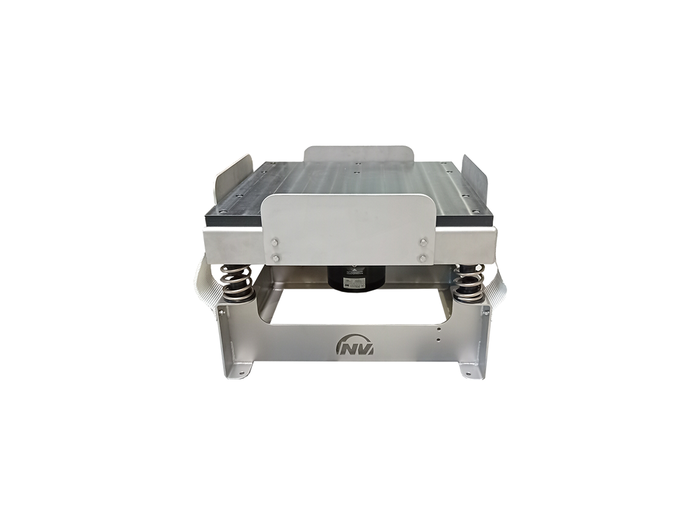

The NTK series pneumatic piston vibrators are particularly suitable for applications requiring high amplitudes and variable stroke. They are commonly used for conveying, compacting and loosening bulk materials, and can also mechanically stimulate or influence processes.

The piston moves freely within the housing. Additional weights can be attached to the protruding piston to increase its movement. This produces sinusoidal low-frequency vibrations at high amplitudes – ideal for applications with substantial material movement.

Frequency is infinitely adjustable via operating pressure, and stroke can be set via the exhaust throttle. NTK piston vibrators start and stop in any mounting position without delay.

For dust-sensitive processes, protective caps and bellows are available to shield the piston from external influences. The specially designed caps of the NTK-AL-MG series are screwed precisely onto the housing, sealing it dust-tight and reliably preventing dirt ingress – even when additional vibration masses are used or in demanding environments.

For optimal selection of the appropriate variant, we recommend individual consultation.

Our technical consultants will be pleased to assist you in selecting and positioning your vibrator or impactor.

Please contact us here.