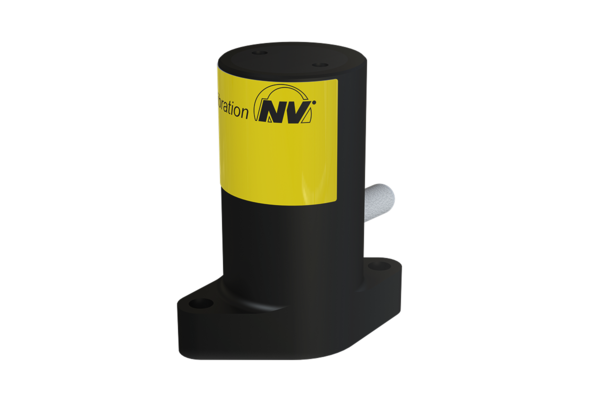

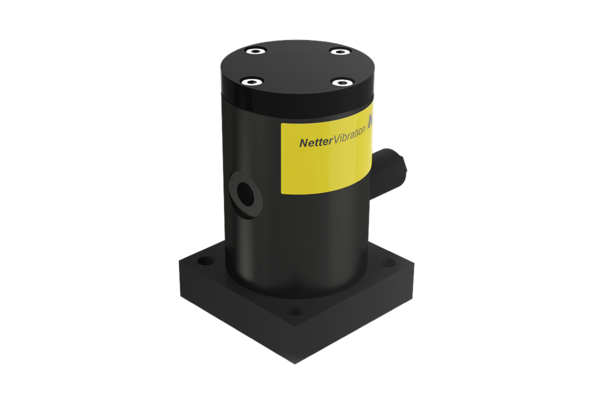

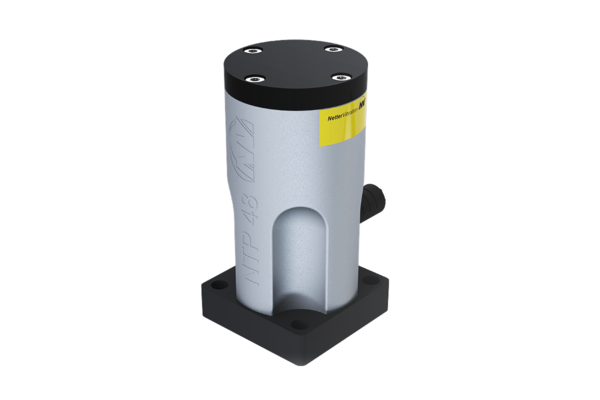

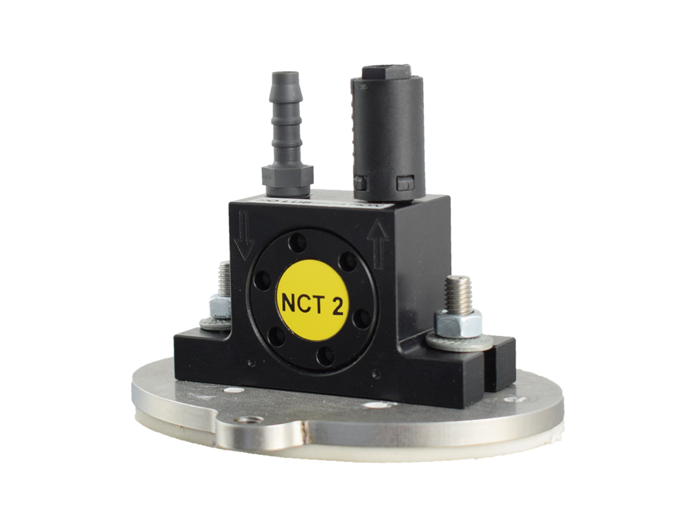

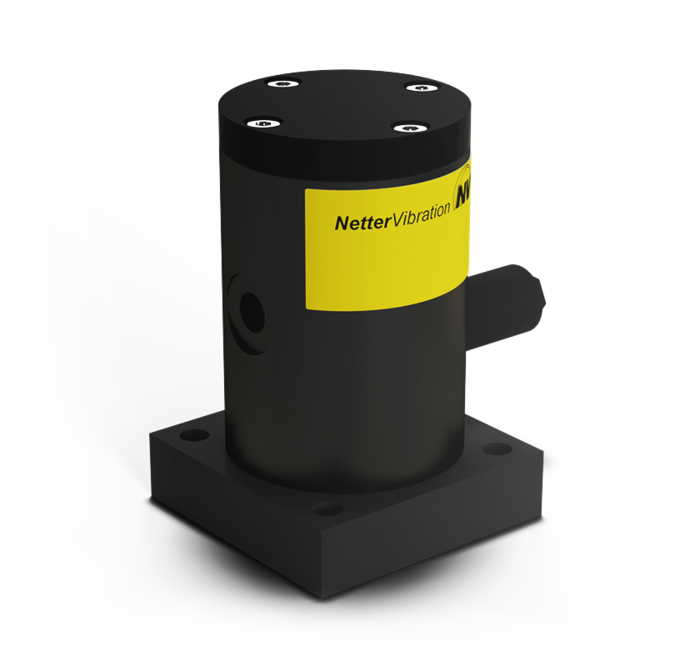

Series NTP Pneumatic Linear Vibrators

The pneumatic rubber mallet – robust, adjustable, versatile

Applications Areas

- Removal of firmly adhering materials in hoppers, silos and bunkers

- Discharge aid for containers in bulk material handling

- Drive unit for vibrating tables, screens and chutes

- Optimisation of material flow across a wide range of industries

Highlights

- Directional linear vibration for precise and targeted impact

- Low-frequency vibrations with medium amplitudes or high-frequency impacts possible

- Infinitely adjustable frequency with separately adjustable stroke

- Can be operated with a rubber hammer effect or as a hard-impact device

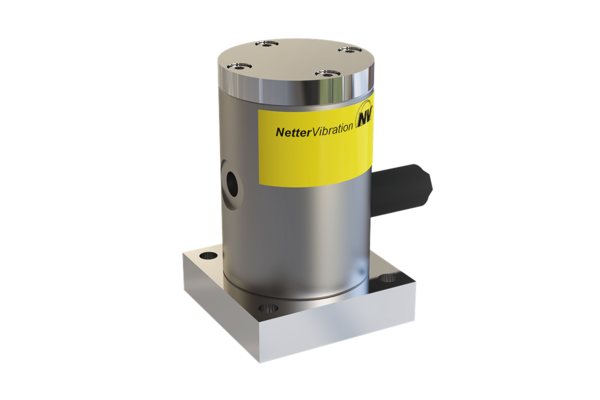

- ATEX-compliant and oil-free versions as well as stainless steel housings available

Datasheet & more

Go to downloadsDescription

The NTP series pneumatic piston vibrators impress with their robust design and flexible range of applications. Their key feature is the ability to generate impacts comparable to a rubber hammer or vibration with high peak accelerations.

They produce a directional linear vibration, making them ideal for removing firmly adhering materials from hoppers, silos and bunkers. In addition, they are used as discharge aids for containers.

The vibration is generated by a freely oscillating differential-pressure piston. In the standard B+C version, the piston strikes an elastomer impact plate, creating the effect of a rubber hammer. Version B operates quietly against an air cushion. Hard-impact versions A are also available.

The frequency is infinitely adjustable via the operating pressure (2–6 bar). A directional control valve is required for operation. Oil-free operation is possible.

For optimal selection of the appropriate variant, we recommend individual consultation.

Our technical consultants will be pleased to assist you in selecting and positioning your vibrator or impactor.

Please contact us here.