NetterVibration offers a wide range of vibration systems and complete plants that optimally support your processes. We have decades of experience in plant engineering for customers from all industries and provide:

- Conveying, dosing, and screening systems

- Vibration and shaking tables

- Additional vibration systems for specialized applications

Highlights

- Long service life and sustainable investment

- ATEX-compliant designs

- Consideration of your available drive power

- Stainless steel constructions, e.g., for use in the food, chemical, or pharmaceutical industries

- Customized plants tailored to your requirements

Our experts are happy to assist you in selecting the solution that suits you best! Contact us today!

Vibrating Feeders, Dosing and Screening Systems

Customised Conveyors and Dosing Systems

Dosing

Feeding

Sieving

Sorting

Show productseries

Vibrating Tables

Serie VTB

Vibrating tables beneath conveyor belts

Loosening

Sorting

Compacting

Show productseries

Vibrating Feeders, Dosing and Screening Systems

Series DosyPack

Dosing Stations

Dosing

Show productseries

Vibrating Feeders, Dosing and Screening Systems

Series FlexiLink

Resonance Conveyor System

Feeding

Show productseries

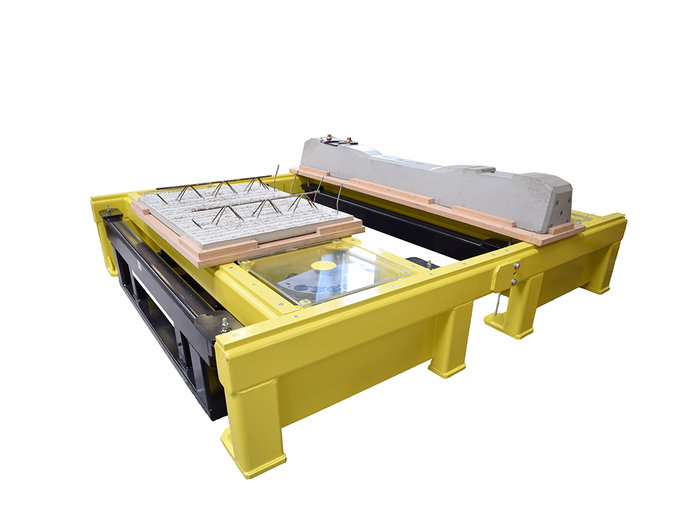

Vibrating Systems

Series GyroShake

Concrete Shaking Station

Concrete compaction

Show productseries

Vibrating Feeders, Dosing and Screening Systems

Series LineDrive

Conveyor Systems

Dosing

Show productseries

Vibrating Systems

Series NHW

Hydraulic Vibrating Unit

Cleaning

Emptying

Show productseries

Vibrating Systems

Series NKH and NKM

Vibrating Cross

Compacting

Show productseries

Vibrating Systems

Series NVI und NHR

Mass concrete compaction system

Concrete compaction

Show productseries

Vibrating Feeders, Dosing and Screening Systems

Series PowerPack

Conveyor Systems

Feeding

Show productseries

Vibrating Systems

Series VectorDrive

Multiple-Shaft Vibration Systems

Loosening

Testing and Simulation

Compacting

Show productseries

Vibrating Tables

Series VT

Standard Vibrating Tables

Loosening

Sorting

Testing and Simulation

Compacting

Packaging

Concrete compaction

Show productseries

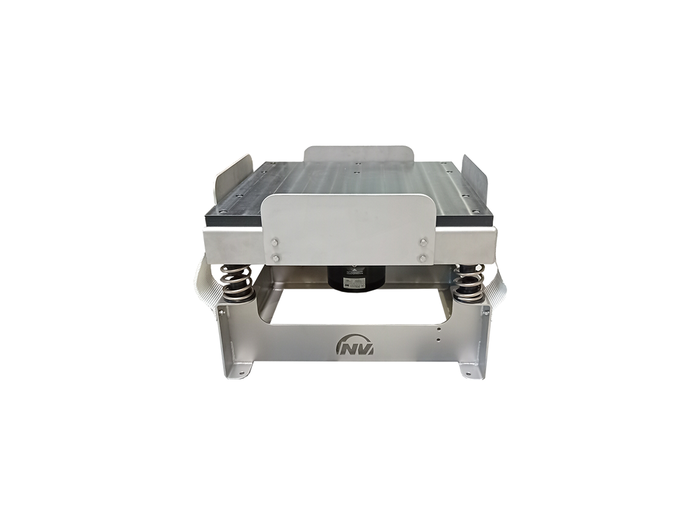

Vibrating Tables

Series VTF

Compact low-profile vibration tables

Loosening

Compacting

Packaging

Show productseries

Vibrating Tables

Series VTR

Vibration Tables for Roller Conveyors

Show productseries

Vibrating Systems

Vibrating Rake

Concrete compaction

Show productseries