The Right Accessories for Maximum Performance

Unlock the full potential of your vibration drives: with high-quality accessories from NetterVibration, your systems operate efficiently, reliably, and economically. Whether controls, mountings, or vibration isolation – every accessory ensures that your vibrators are perfectly integrated and your processes are optimally supported. Our specialists are happy to assist you in selecting the right solution for your application!

Highlights

- Optimal control and operation of your systems at minimal cost

- Maximum energy transfer through robust mounting systems

- Durable and low-maintenance components

- Measurement and monitoring systems for safe and efficient processes

- Vibration isolation systems to improve vibration performance

- Specialized accessories for pneumatic and concrete vibrators

Control Systems

AP Timer

Show productseries

Vibration Isolation Systems

Blade Springs

Conveying systems

Show productseries

Vibration Isolation Systems

Coil Springs

Made of Stainless Steel

Show productseries

Fixing Devices

Customised Consoles for Vibrators

Show productseries

Accessories for Pneumatic Vibrators

Miscellaneous accessories

From screws to hoses

Show productseries

Vibration Isolation Systems

Pneumatic Spring Bellows

Vibration Isolation

Show productseries

Accessories for Pneumatic Vibrators

Serie HVI, LVI und MVI

Pneumatic Valves

Show productseries

Fixing Devices

Series ASB

Weld-On Consoles

Show productseries

Accessories for Concrete Vibrators

Series FSW

Frequency and Voltage Converters

Show productseries

Control Systems

Series NAS and NSS

Sequence Controls

Show productseries

Fixing Devices

Series NBS Electro

Fastening Sets for Electric External Vibrators

Show productseries

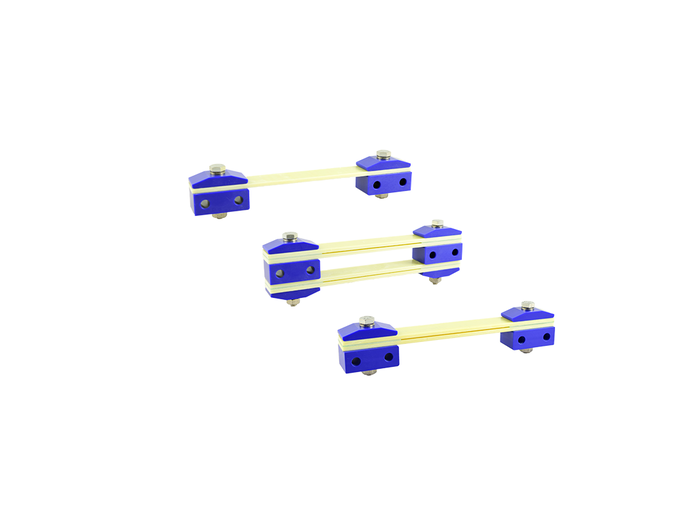

Fixing Devices

Series NBS Pneumatic

Fastening Sets for pneumatic impactors

Show productseries

Accessories for Concrete Vibrators

Series NFC

Electronic Frequency Converters

Show productseries

Accessories for Concrete Vibrators

Series NFG

Diesel Generators

Show productseries

Fixing Devices

Series NKK

Glueing Consoles

Show productseries

Vibration Isolation Systems

Series NRE, NTE, NOF and NAP

Rubber Elements

Show productseries

Accessories for Pneumatic Vibrators

Series NWE, NFR and NOE

Pneumatic Maintenance Units

Show productseries

Control Systems

Series SRF, NFU and ATV

Variable-Frequency Controls

Show productseries

Fixing Devices

Series SVS

Quick-Clamping Brackets

Show productseries

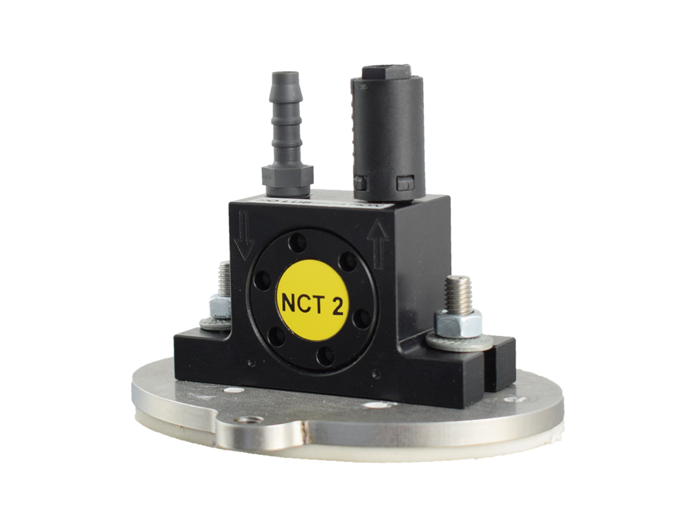

Fixing Devices

Series VAC

Vacuum Fixing Devices

Show productseries

Measuring and Monitoring Systems

Series VibroMonitor

Vibration Monitoring System

Show productseries

Measuring and Monitoring Systems

Series VibroScanner

Vibration Measuring System

Show productseries

Measuring and Monitoring Systems

Sirometer

Frequency Measuring Device

Show productseries

Fixing Devices

Sound Protection Hood

Show productseries

Measuring and Monitoring Systems

Stroboscope

Hand-Held LED

Show productseries