The Right Pneumatic Vibrator for Every Application

Discover the power of modern pneumatic vibration technology: for reliable material flow, effective compaction, gentle conveying and emptying. Whether rotary or piston vibrator or impactor – each type offers its own strengths. Our specialists are happy to assist you in selecting the right solution for your task.

Highlights

- Compact and robust design, lightweight

- Long service life, low maintenance

- Steplessly adjustable

- High power-to-weight ratio

- Quiet and environmentally friendly

Rotary Vibrators

Series NCB

Pneumatic Ball Vibrator

Cleaning

Emptying

Feeding

Loosening

Sorting

Show productseries

Rotary Vibrators

Series NCR

Pneumatic Roller Vibrators

Cleaning

Emptying

Loosening

Show productseries

Rotary Vibrators

Series NCT

Pneumatic Turbine Vibrator

Cleaning

Emptying

Show productseries

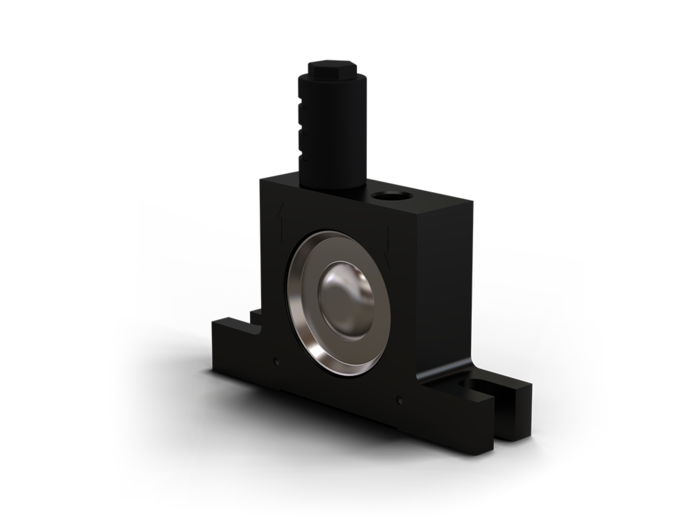

Impactors

Series NHK

High-Frequency Impactors

Cleaning

Emptying

Loosening

Compacting

Show productseries

Linear Vibrators

Series NTK

Pneumatic Piston Vibrator

Cleaning

Dosing

Emptying

Feeding

Loosening

Sieving

Sorting

Testing and Simulation

Compacting

Packaging

Show productseries

Linear Vibrators

Series NTP

Pneumatic Linear Vibrators

Cleaning

Dosing

Emptying

Feeding

Loosening

Sieving

Sorting

Testing and Simulation

Compacting

Show productseries

Linear Vibrators

Series NTS

Pneumatic Piston Vibrator

Cleaning

Dosing

Emptying

Feeding

Loosening

Sieving

Sorting

Testing and Simulation

Compacting

Show productseries

External Vibrators

Series NTV

Pneumatic External Vibrator

Cleaning

Emptying

Loosening

Compacting

Concrete compaction

Show productseries

Internal Vibrators

Series NVV

Pneumatic Internal Vibrators

Concrete compaction

Show productseries

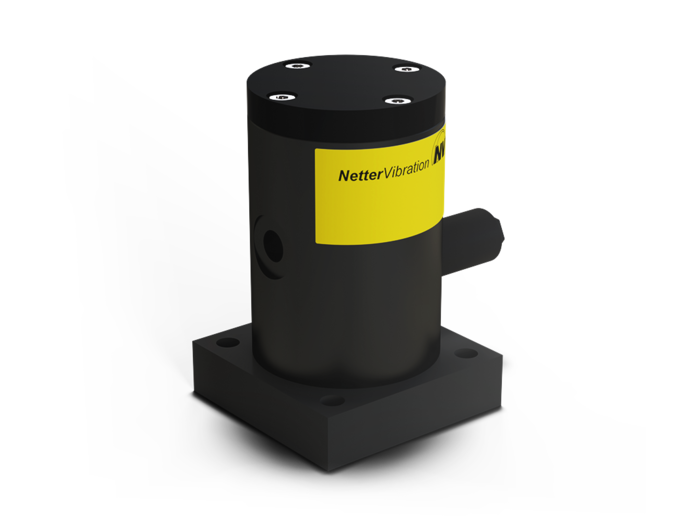

Impactors

Series PKL

Pneumatic Impactors

Cleaning

Emptying

Compacting

Testing and Simulation

Show productseries